Pelatihan Komputer Pelajar Sekitar Tambang Satui

Pemberdayaan Masyarakat PT Arutmin Indonesia - Site Asamasam

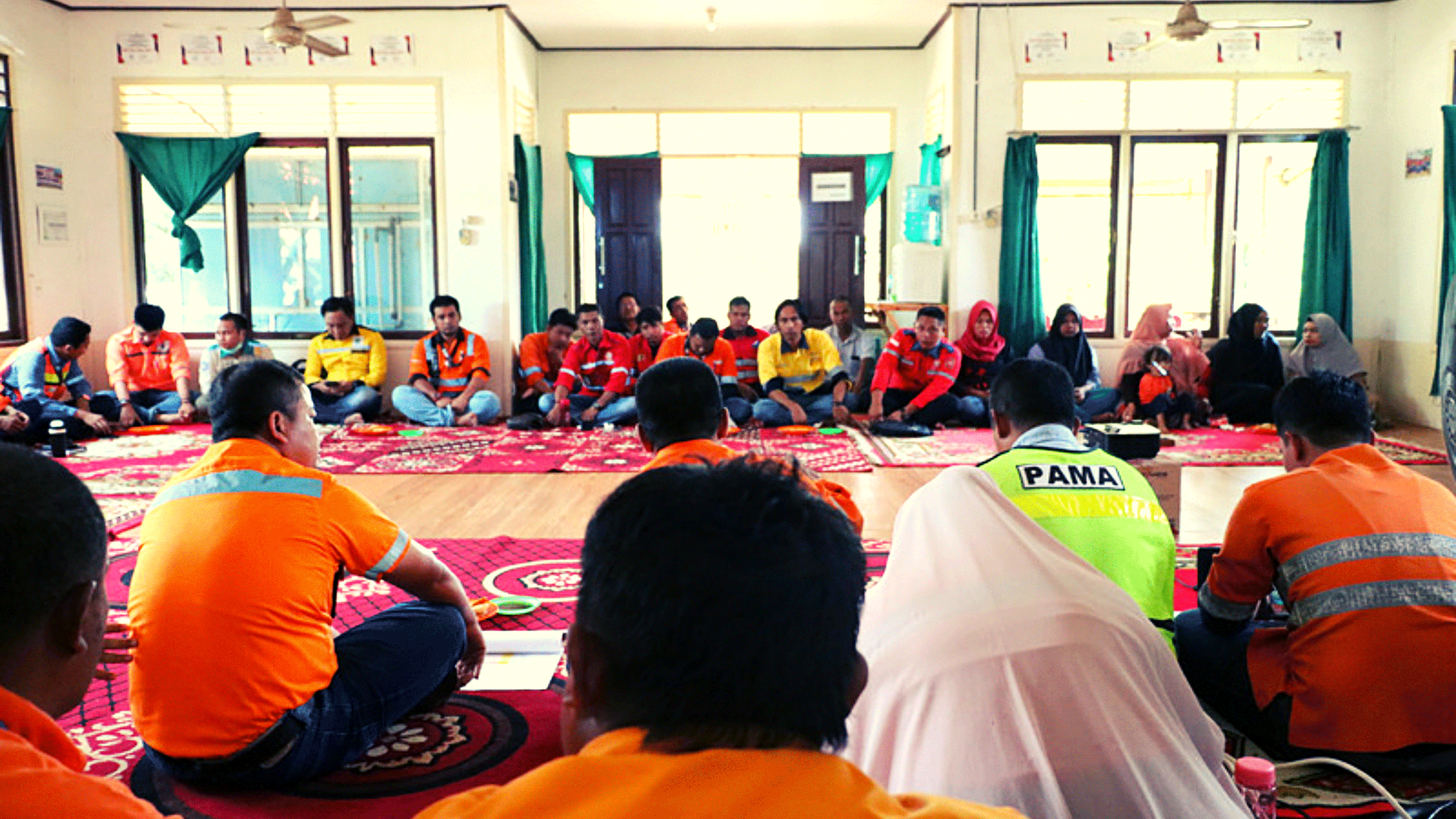

Musyawarah dalam Program Pemberdayaan Masyarakat PT Arutmin Indonesia - Site Satui

Pengembangan Peternakan dan Pupuk Organik

Puskesmas PT Arumin Indonesia - Site Senakin

Pengembangan Budidaya Tanaman dan Peternakan PT Arutmin Indonesia - Site Senakin

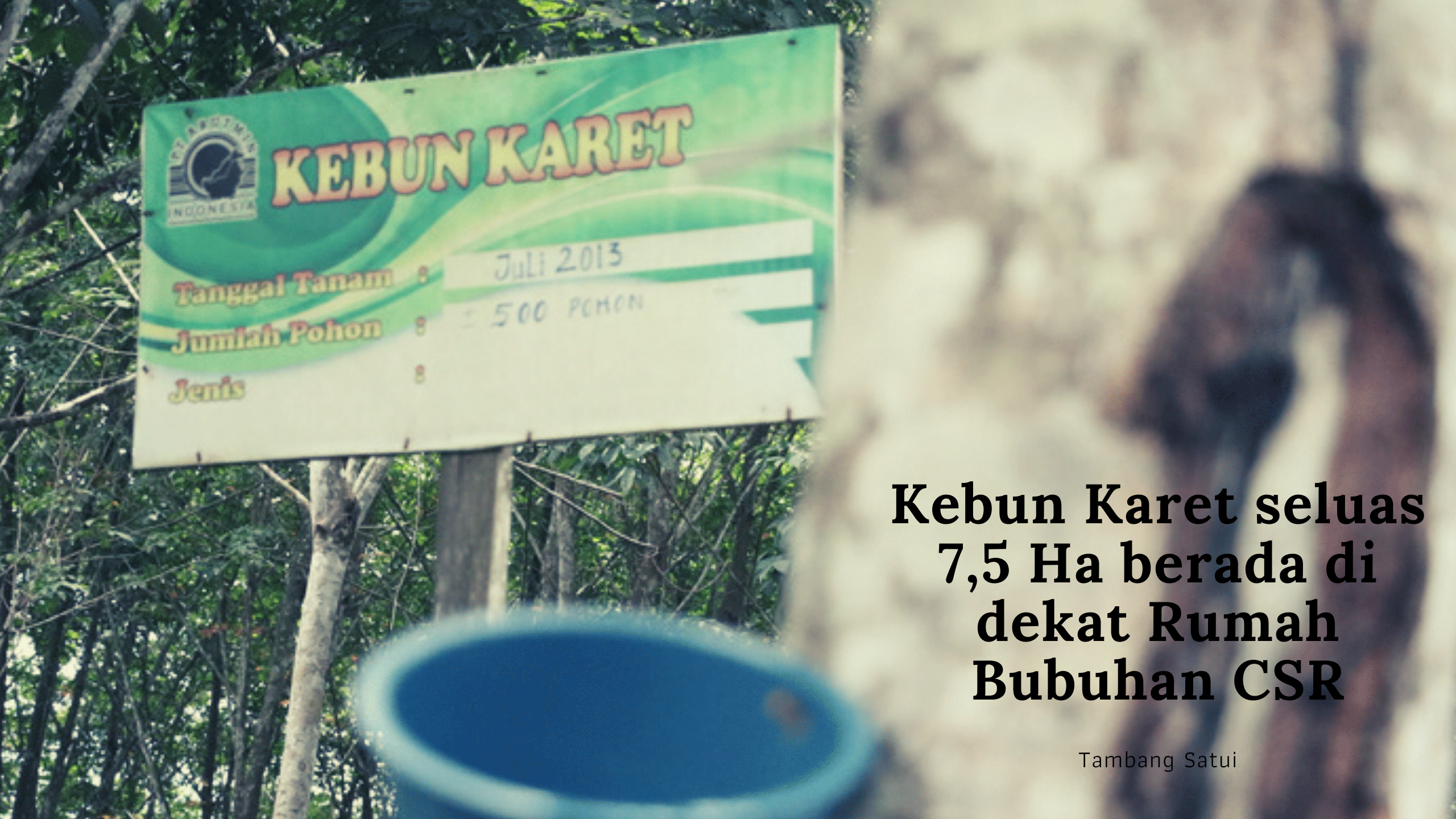

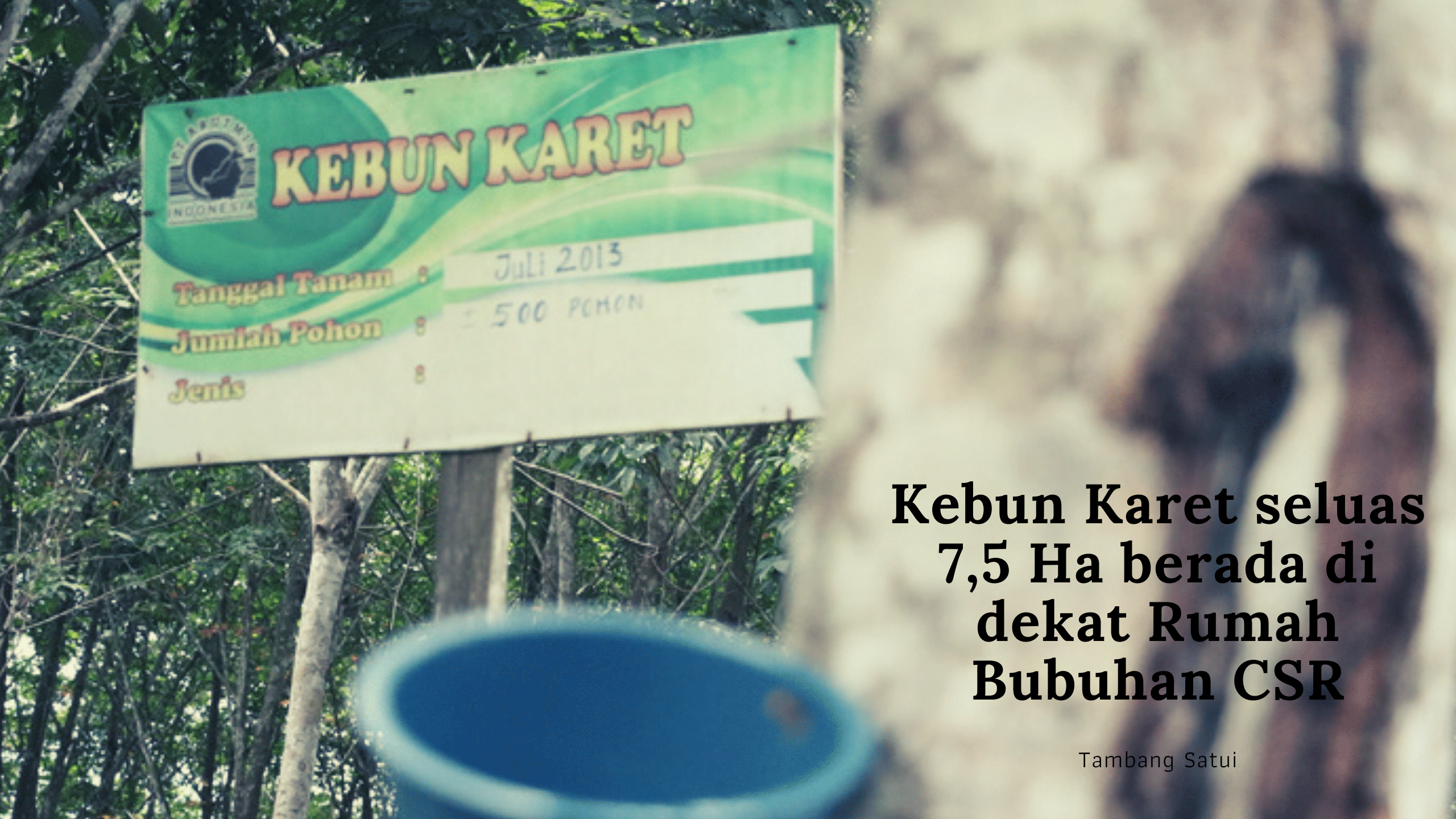

Perkebunan Karet Hasil Binaan PT Arutmin Indonesia - Site Satui

SustainabiltyCorporate Social Responsibility

Our commitment to Community Development and Empowerment (PPM) is implemented through sustainable programs aiming to improve the quality of life for the community around the mine.

The programs focus on eight areas; education, health, real income levels (employment), economic, social and cultural independence, sustainable environmental management, the formation of community institutions and infrastructure development.

We believe by strengthening partnerships and cooperation with the government, employees and local communities will bridge to actualize one of the company's goals: to build a prosperous mine-circle community.

As a company that has been operating for more than 38 years, Arutmin feels responsible for the welfare of the community around the operational area that is spread into three districts; Tanah Laut, Tanah Bumbu and Kotabaru. Therefore, our PPM program is an important part of the company's business in achieving our CSR mission.

Arutmin is committed to participating in regional development in each of its mining operations, by continuing to build and improve community structures to become more empowered to create independence and prosperity in the local community.

Safety Training

SustainabiltyOccupational Safety and Health

Occupational Safety and Health is the main value that Arutmin pays attention to in carrying out operational activities.

Safety aspects of work operations are run according to the Mining Safety Management System (SMKP) under the Good Mining Practice (GMP) regulations. Arutmin's commitment to achieving zero accident mining operations includes the implementation and improvement of the Occupational Safety and Health Management System (SMK3).

The application of the Mining Safety Management System (SMKP) is required for all employees and contractors involved in Arutmin’s operational activities. The system is designed and developed in line with the company’s needs to meet the requirements and applicable government regulations.

The Mining Safety Management System (SMKP) will be evaluated and updated regularly to ensure it remains relevant and effective during the stages of the company’s development and the mining industry, particularly coal.

Hasil Reklamasi Pasca Tambang

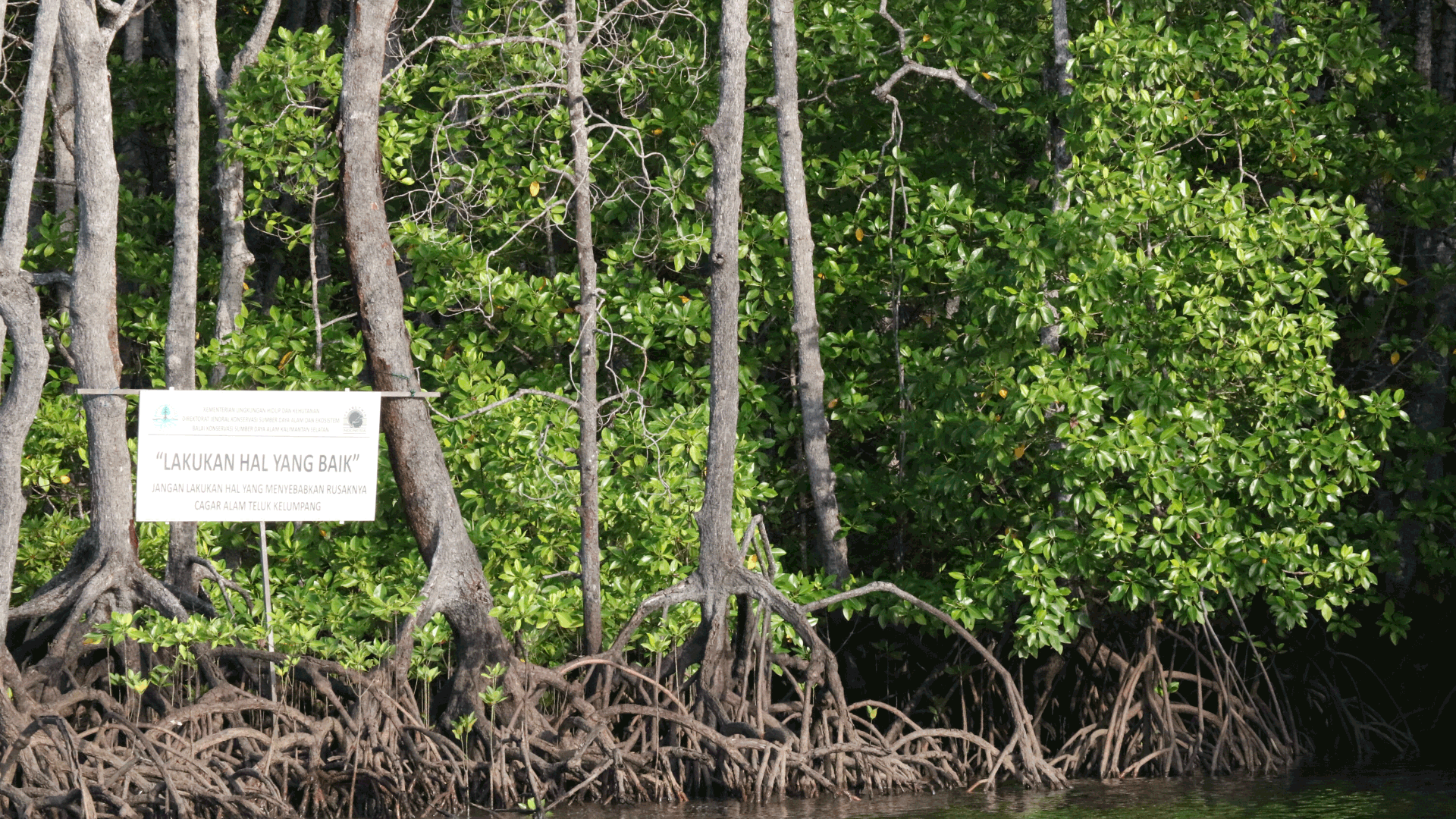

Konservasi Hutan Mangrove

Perkebunan Karet Hasil Binaan PT Arutmin Indonesia - Site Satui

Reklamasi PT Arutmin Indonesia - Site Satui

Program CSR PT Arutmin

SustainabiltyEnvironmental Conservation

All mining activities at Arutmin are managed through proper environmental management to ensure minimal effect on the environment.

Starting from the land clearing process, topsoil removal, excavation of overburden, coal extraction, overburden re-closure, rearrangement of landscape shape, redistribution of topsoil, revegetation, waste handling, settlements and offices, to port operations, all stages are done comprehensively by implementing environmental management and supervision under the Analysis on Environmental Impacts and Environmental Management System (AMDAL) and Environmental Management System that accommodates the existing regulations.

Arutmin's Environmental Management System is designed and developed in line with the company’s needs to meet the minimum requirements in the elements of ISO 14001: 2015. The implementation of this Environmental Management System will ensure that environmental management is carried out regularly to monitor the quality of water, air, B3 waste, dust and noise, and to ensure good conservation of natural resources, a comprehensive and responsible reclamation and recovery process.

This system will also be regularly evaluated and updated to ensure it remains relevant and effective following the stages of the company's development effective under the stages of the company’s development and the mining industry, particularly coal.

Environment, Society, and Safety Management in Mining

1. Company Policy

PT Arutmin Indonesia is committed to meeting the standards of Environment, Society, and Safety Management in Mining at every one of their work locations to achieve the best work performance and create a safe, healthy, sustainable, and harmonious work environment.

The role of occupational safety and health in coal mining activities is very important, therefore our actions strive to:

-

Obey the law and regulations in Environment, Society, and Safety Management in Mining and uphold human rights applicable in Indonesia.

-

Prevent accidents, occupational diseases, environmental pollution and social problems by executing an integrated Environment, Society, and Safety Management in Mining program.

-

Provide a safe, productive and efficient work environment by ensuring the company’s asset viability and security and applying the concept of integrated security to minimize disruption to the sustainability of the company's operations.

-

Develop the Environment, Society, and Safety Management in the Mining system to identify, evaluate, and control the risks and impact on employees, the environment, and society.

-

Support health programs in preventing infectious diseases including HIV/AIDS and misuse of narcotics, alcohol, psychotropic, and other addictive substance.

-

Periodically review the policy and implementation of Environment, Society, and Safety Management in the Mining system to ensure continuous performance improvement.

2. Employee Rights and Obligations

- Personal Protective Equipment (PPE) and Safety Equipment

- Standard Operating Procedure (SOP)

- Health Services and Facilities

- K3 Campaign

- Employee Education and Training

- Work Environment

- Emergency Response

Every person entering PT Arutmin Indonesia's work and the operational area will be provided with free Personal Protective Equipment (PPE) and safety equipment that must be used properly. Other than being required to use PPE correctly and according to its purpose, they are also required to take care of the PPE from damage before its usage time limit.

Work procedures are the basics that must be learnt and implemented by every employee of PT Arutmin Indonesia. Working according to procedures will minimize risk and injury due to accidents. Every job description in PT Arutmin Indonesia has been well documented in the SOP.

PT Arutmin Indonesia holds high concern for the health of its employees. Through a health inspection program, employees can easily control and improve their health status. The company also collaborates with several clinics and hospitals to support the occupational health program to remain sustainable. Besides that, the blood donor and HIV/ AIDS counselling program have become an annual program to increase knowledge about the importance of HIV/ AIDS prevention. Our nutrition program also helps control food consumption to avoid the risk of health diseases.

The K3 campaign program is a design of safety and health care in each work line. PT Arutmin Indonesia continuously promotes campaigns related to work safety and health to employees. The campaign aim is to provide information, whether it is new information or reminder information regarding the importance of safety and health. The company delivers this campaign through meetings, print media, audio media, or visual media so that the information is received immediately and applied properly by the employees.

Every employee working at PT Arutmin Indonesia receive full support to develop themselves. One of the platforms is through education and training. Every employee has the right to volunteer for education or training that is useful to support his/her performance in the company.

A safe and comfortable environment results in productive employees. PT Arutmin Indonesia conducts a conducive work environment control for its employees through measurement and evaluation of the work environment and its follow - up.

Emergency response is a fundamental matter that must be understood by all employees of PT Arutmin Indonesia. Prevention of the risks that can occur in the workplace is delivered through training, as well as the implementation of risk management to anticipate the potential hazards that can occur.

3. SIAP Program (Safety Indicator for Arutmin Performances)

The SIAP program is one of the mining safety programs owned by PT Arutmin Indonesia. It owns the evaluation for key performance based on occupational safety and health programs and safety mining operations. The SIAP program measures three core indicators; the Leading Indicator, the Process Indicator, and the Lagging Indicator. Through the SIAP program, we can find out the progress of the work safety and health program carried out by PT Arutmin Indonesia.

| No | Indicator | Average | |

|---|---|---|---|

| 1 | Leading Indicator | 95.15% | |

| 2 | Process Indicator Arutmin | 92.94% | |

| 3 | Process Indicator Contractor | 83.79% | |

| 4 | Lagging Indicator | 72.29% | |

| % SIAP | 86.04% |

4. Mining Safety Management System

PT Arutmin Indonesia complies with government regulations regarding the implementation, assessment and reporting of the Mining Safety Management System. This is our practice of corporate responsibility towards the government to benefit the welfare of its employees in the field of safety and health.

This system is run through the K3 Mining management approach and Mining KO that contains 7 elements; Policy, Planning, Organization and Personnel, Implementation, Evaluation and Follow-up, Documentation, as well as Management Review and Performance Improvement. PT Arutmin Indonesia cares about the safety and health of its employees and continuously evaluates every safety and health program in the company. The evaluation becomes an input to follow up on the prevention and treatment towards potential hazards and illnesses around the company locations.

5. Safety, Health and Environmental Awards

- SITE SENAKIN

- SITE SATUI

- SITE BATULICIN

- SITE ASAMASAM

- SITE KINTAP

- NORTH PULAU LAUT COAL TERMINAL (NPLCT)

Following are the safety awards in mining received by the Site Senakin since the beginning of its operations:

From The Ministry of Energy and Mineral Resources

| YEAR | AWARD |

|---|---|

| 2001 | Aditama |

| 2002 | Aditama |

| 2004 | Aditama |

| 2005 | Aditama |

| 2006 | Utama |

| 2007 | Aditama |

| 2008 | Aditama |

| 2009 | Aditama |

| 2010 | Utama |

| 2011 | Aditama + Trophy Upakarti |

| 2012 | Utama |

| 2013 | Utama |

| 2021 | Utama |

From The Indonesian Ministry of Labour

| YEAR | AWARD |

|---|---|

| 2012 | Zero Accident Award |

| 2013 | Zero Accident Award |

From The Governor of South Kalimantan Province

| YEAR | AWARD |

|---|---|

| 2012 | Zero Accident Award |

| 2013 | Zero Accident Award |

Following are the safety awards in mining received by the Site Satui since the beginning of its operations:

From The Ministry of Energy and Mineral Resources

| YEAR | AWARD |

|---|---|

| 1996 | Aditama + Upakarti Trophy |

| 2001 | Aditama |

| 2002 | Aditama |

| 2004 | Aditama + Upakarti Trophy |

| 2009 | Aditama |

| 2010 | Aditama |

| 2011 | Aditama |

| 2013 | Aditama |

| 2016 | Aditama |

| 2017 | Aditama |

From The Indonesian Ministry of Labour

| YEAR | AWARD |

|---|---|

| 2008 | Zero Accident Award |

| 2009 | Zero Accident Award |

| 2010 | Zero Accident Award |

| 2016 | Zero Accident Award |

| 2017 | Zero Accident Award |

From The Governor of South Kalimantan Province

| YEAR | AWARD |

|---|---|

| 2008 | Zero Accident Award |

| 2009 | Zero Accident Award |

| 2010 | Zero Accident Award |

| 2016 | Zero Accident Award |

| 2017 | Zero Accident Award |

Following are the safety awards in mining received by the Site Batulicin since the beginning of its operations:

From The Ministry of Energy and Mineral Resources

| YEAR | AWARD |

|---|---|

| 2009 | Aditama |

| 2010 | Utama |

| 2011 | Aditama |

| 2013 | Utama |

| 2016 | Utama |

| 2017 | Utama |

| 2018 | Aditama |

| 2021 | Utama |

From The Indonesian Ministry of Labour

| YEAR | AWARD |

|---|---|

| 2012 | Zero Accident Award |

| 2013 | HIV-AIDS Prevention Award |

From The Governor of South Kalimantan Province

| YEAR | AWARD |

|---|---|

| 2012 | Zero Accident Award |

| 2013 | Zero Accident Award |

| 2013 | HIV-AIDS Prevention Award |

Following are the safety awards in mining received by the Site Asamasam since the beginning of its operations:

From The Ministry of Energy and Mineral Resources

| YEAR | AWARD |

|---|---|

| 2009 | Aditama |

| 2010 | Utama |

| 2011 | Utama |

| 2013 | Pratama |

| 2016 | Utama |

| 2017 | Utama |

| 2018 | Utama |

| 2021 | Pratama |

From The Indonesian Ministry of Labour

| YEAR | AWARD |

|---|---|

| 2010 | Zero Accident Award |

| 2017 | Zero Accident Award |

From The Governor of South Kalimantan Province

| YEAR | AWARD |

|---|---|

| 2010 | Zero Accident Award |

| 2017 | Zero Accident Award |

Following are the safety awards in mining received by the Site Kintap since the beginning of its operations:

From The Ministry of Energy and Mineral Resources

| YEAR | AWARD |

|---|---|

| 2013 | Utama |

| 2014 | Pratama |

| 2016 | Pratama |

| 2017 | Pratama |

| 2018 | Utama |

| 2021 | Pratama |

From The Indonesian Ministry of Labour

| YEAR | AWARD |

|---|---|

| 2013 | Zero Accident Award |

| 2017 | Zero Accident Award |

| 2018 | Zero Accident Award |

From The Governor of South Kalimantan Province

| YEAR | AWARD |

|---|---|

| 2013 | Zero Accident Award |

| 2015 | Application of SMK3 |

| 2017 | Zero Accident Award |

| 2018 | Zero Accident Award |

Following are the safety awards in mining received by the NPLCT since the beginning of its operations:

From The Ministry of Energy and Mineral Resources

| YEAR | AWARD |

|---|---|

| 2002 | Aditama + Upakarti Trophy |

| 2003 | Aditama + Upakarti Trophy |

| 2004 | Aditama + Upakarti Trophy |

| 2005 | Aditama + Upakarti Trophy |

| 2006 | Aditama + Upakarti Trophy |

| 2008 | Aditama + Upakarti Trophy |

| 2009 | Aditama |

| 2010 | Aditama |

| 2011 | Aditama |

| 2013 | Utama |

| 2015 | Utama |

| 2016 | Utama |

| 2017 | Utama |

| 2018 | Utama |

From The Indonesian Ministry of Labour

| YEAR | AWARD |

|---|---|

| 2004 | Zero Accident Award |

| 2005 | Zero Accident Award |

| 2007 | Zero Accident Award |

| 2008 | Zero Accident Award |

| 2009 | Zero Accident Award |

| 2010 | Zero Accident Award |

| 2011 | Zero Accident Award |

| 2012 | Zero Accident Award |

| 2013 | Zero Accident Award |

| 2014 | Zero Accident Award |

| 2016 | Zero Accident Award |

| 2017 | Zero Accident Award |

| 2018 | Zero Accident Award |

From The Governor of South Kalimantan Province

| YEAR | AWARD |

|---|---|

| 2012 | Zero Accident Award |

| 2013 | Zero Accident Award |

| 2014 | Zero Accident Award |

| 2016 | Zero Accident Award |

| 2017 | Zero Accident Award |

| 2018 | Zero Accident Award |