Bussiness InfoMarketing

Coal production

Arutmin owns high-quality coal reserves with high calorific value and an abundant amount of environmentally-friendly young coal. Arutmin produces a variety of different types of coal at all of our mines. Therefore, Arutmin offers alternative coal products, ranging from high-calorie coal, environmentally friendly low-calorie coal, and specially blended products.

Bituminous Coal

The Senakin Site, Satui Site, and Batulicin Site produce high-calorie quality coal. This type of coal releases a small amount of ash and contains a small amount of high-calorie sulfur. Arutmin is also capable of producing blended coal with certain specifications to meet diverse consumer needs.

Ecocoal

Ecocoal is produced at the Asamasam and Kintap Site. Ecocoal is rated environmentally friendly, containing a low level of dirt, particularly less dust (5.5% air-dried) and low sulfur (0.3% air-dried), which results in clean combustion. The usage of ecocoal in power plants is capable of meeting SOx and NOx disposal regulations without having to install or operate expensive FGD and NOx disposal machines. Ecocoal combustion makes the boiler operate efficiently and accurately.

| ECOCOAL | Arutmin 5000 | Arutmin 5300 | Arutmin 5500 | Arutmin 5800 | Arutmin 5900 | Arutmin 6250 | Arutmin 6300 | Arutmin 6500 | |

|---|---|---|---|---|---|---|---|---|---|

Total Moisture,% as received basis |

35.5 | 25.5 | 22.5 | 20.0 | 16.5 | 17.5 | 10.0 | 11.0 | 11.0 |

Proximate Analysis,% air dried basis |

|||||||||

| Moisture | 20.5 | 14.0 | 12.0 | 11.0 | 9.0 | 9.5 | 4.5 | 5.5 | 5.5 |

| Ash | 5.5 | 8.0 | 9.0 | 8.0 | 9.0 | 7.5 | 12.5 | 10.0 | 8.0 |

| Volatile Matter | 38.5 | 39.5 | 40.0 | 41.0 | 42.0 | 42.0 | 41.0 | 43.0 | 43.5 |

| Fixed Carbon | 35.5 | 38.5 | 39.0 | 40.0 | 40.0 | 40.0 | 41.5 | 41.5 | 43.0 |

Sulfur,% air dried basis |

0.35 | 0.54 | 0.75 | 0.65 | 0.75 | 0.65 | 1.00 | 0.80 | 0.80 |

Calorific Value,kcal/kg |

|||||||||

| Gross air dried | 5117 | 5727 | 5941 | 6119 | 6335 | 6335 | 6632 | 6689 | 6902 |

| Gross as received | 4200 | 5000 | 5300 | 5500 | 5800 | 5800 | 6250 | 6300 | 6500 |

| Net as Received | 3844 | 4665 | 4980 | 5178 | 5178 | 5480 | 5931 | 5993 | 6194 |

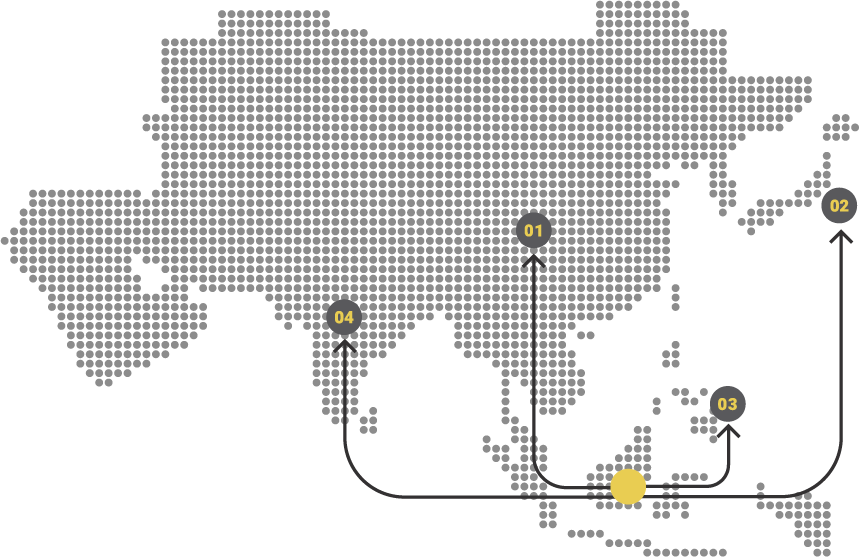

Export

2024

- China

- Japan

- Philippines

- India

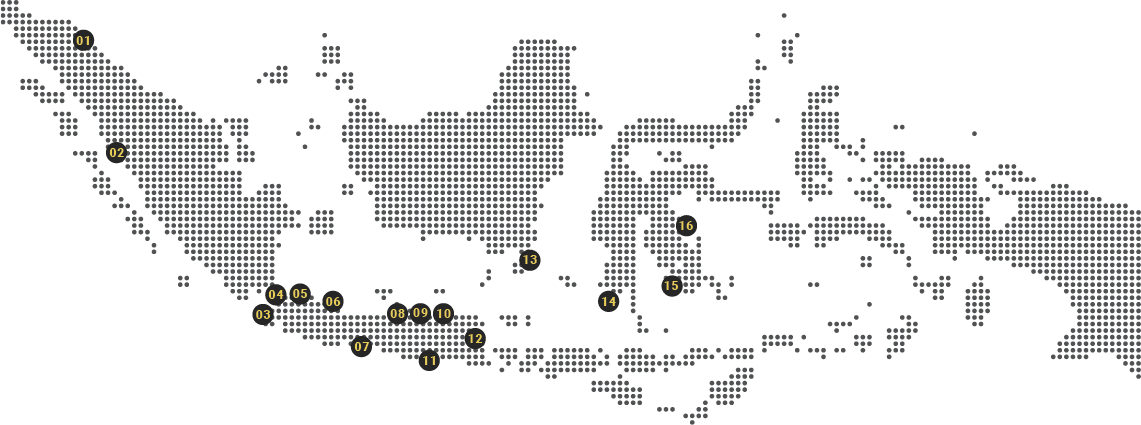

Grand Total Mining

Domestik

Pln

PLTU Pangkalan Susu

PLTU Teluk Sirih

PLTU Labuan

PLTU Surajaya

PLTU Lontar

PLTU Indramayu

PLTU Adipala

PLTU Rembang

PT Semen Indonesia

PLTU Tanjung Awar-awar

PLTU Pacitan

PLTU Paiton

PLTU Asamasam

PLTU Takalar

PT Antam

PT SMI

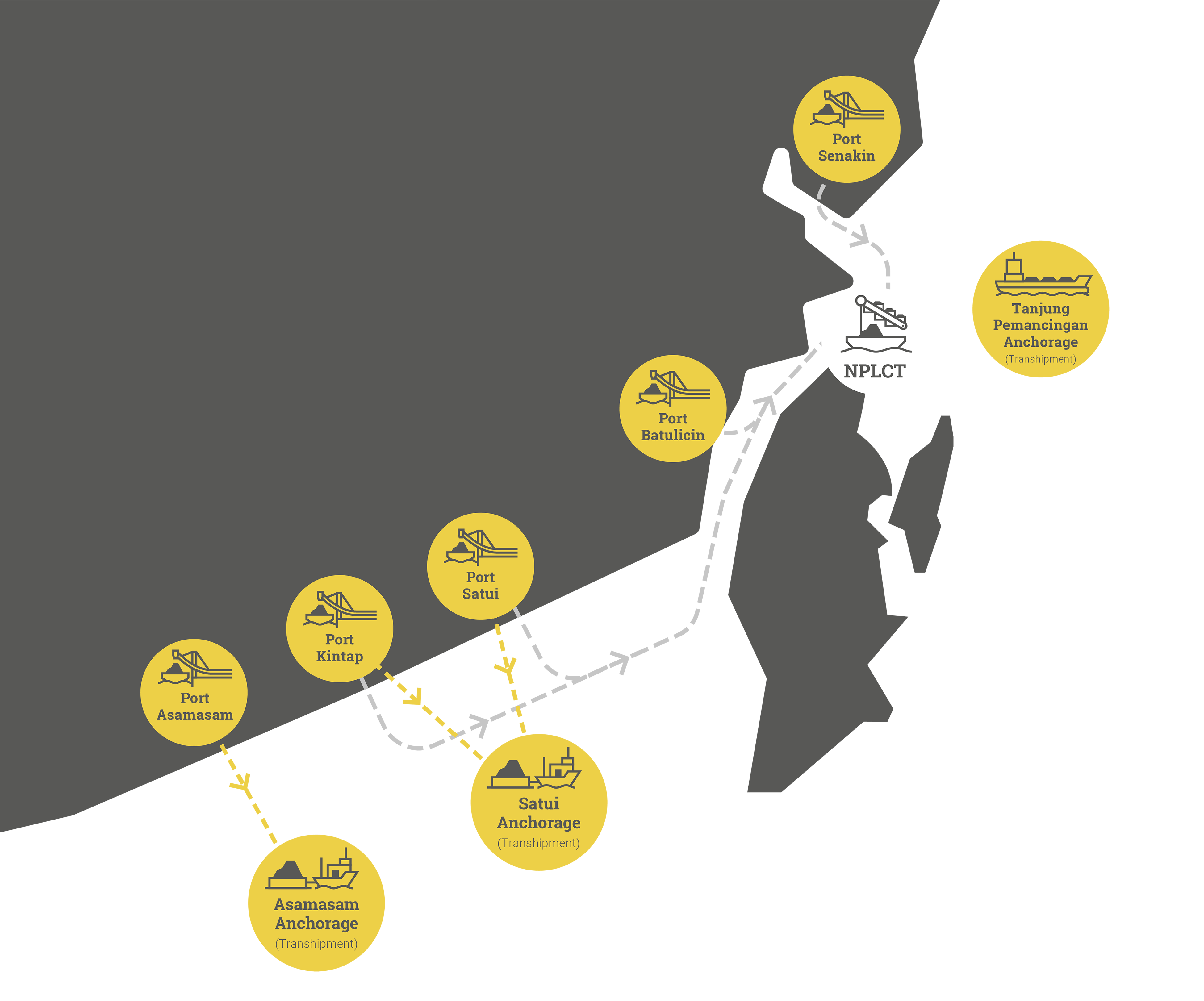

Data Anchorage (Transhipment)

PT ARUTMIN INDONESIA PORT GUARANTEED LOADING RATES

1. North Pulau Laut Coal Terminal (NPLCT)

| Cargo Lifted (metric tons) |

Guaranteed Loading Rates (metric tons/weather working day) |

|---|---|

| 0 - 20,000 | 10,000 |

| 20,001 - 45,000 | 20,000 |

| 45,001 - 75,000 | 25,000 |

| Above 75,000 | 30,000 |

2. Loading Anchorage

2.1 Floating Crane (FC)

| Cargo Lifted (metric tons) |

Guaranteed Loading Rates (metric tons/weather working day) |

|---|---|

| 0 - 35,000 | 8,000 |

| 35,000 - 150,000 | 10,000 |

2.2 Geared Vessel (Loading with the Vessel’s Cranes)

| Cargo Lifted (metric tons) |

Guaranteed Loading Rates (metric tons/weather working day) |

|---|---|

| 0 - 75,000 | 10,000 ( 4 x 25 Mt SWL + 4 x 12 CBM grab) |

Notes

All guaranteed loading rates per weather working day including Saturdays, Sundays and public holidays, but excluding the major Indonesian holidays.

The guaranteed loading rates shall relate to the parcel size (actual cargo lifted) and not to the size of the vessel or shipment being loaded.

The standard loading rates shall apply to vessels which comply with the regulations and restrictions.

Vessels exceeding the restrictions or not fulfilling the minimum requirements must agree to a loading rate with Arutmin before the vessel's arrival.

Coal Transport And Loading Facilities

Processing Facilities

- Crusher Asam Asam

- Crusher Kintap

- Crusher Pelabuhan Satui

- Crusher Pelabuhan Batulicin

- Washing Plan Senakin DMP & Jig Plant

Loading Facilities

- Stacker, Reclaimer & Shiploader NPLCT

- Continuous Barge Unloader (CBU) NPLCT

- Tongkang

- Load Out Conveyor Asam Asam

- Overland Conveyor (OLC) Asam Asam

- Load Out Conveyor Kintap

- Overland Conveyor (OLC) Kintap

- Load Out Conveyor Satui

- Load Out Conveyor Batulicin

- Load Out Conveyor Senakin SBL & AT02

Coal-Transport

OverLandConveyor

Realizing the importance of transportation in the coal business chain, Arutmin is equipped with an excellent infrastructure and transportation system.

Some facilities such as the Coal Processing Plant (CPP) and Port Load Out are equipped at every site. Other facilities such as Overland Conveyor (OLC) are provided at several locations.

These supporting facilities are continuously improved in line with the needs and current technology development. The presence of NPLCT Port has become a crucial milestone towards a smooth process of loading and transporting coal to our consumers

Quality Assurance

Arutmin implements the best quality management procedures worldwide for our coal production process.

From mining to shipping, the coal runs through sampling and testing at each stage. Metal and magnet detectors are installed in all crushing and washing facilities in the loading and unloading port of the barge and the transport terminal, Port NPCLT.

A dedicated Logistics and Quality Team constantly monitors the coal production process for 24 hours. This is done to ensure the quality of the coal meets the specifications listed in the contract.

1. Dust Control

Dust control is done by adding 1% moisture to equilibrium dust using the Dust Suppression System (DSS) located at the CPP & Port.

The amount of water for DSS must be maintained, therefore a Sea Water Reverse Osmosis (SWRO) facility is built so the water is constantly available through all seasons.

2. Coal Quality Monitoring Using Real-Time Analyzer

The analysis of the Coal Quality Scanner on CPP is done instantly every 2 minutes, which helps monitor Good Mining Practice activities and loading accuracy.

3. Prevention of Metal Contamination

Our commitment to providing double protection against metal contamination, such as gear buckets, gear crushers, plates, pipes, bolts, wires, etc., is done by using metal detectors and magnetic separators.

4. Non-Metal & Oversized Contamination Prevention

The prevention of non-metal and oversized contamination, particularly oversized coal, is done by installing Screening 150 mm at the end of the OLC process.

This is to ensure a homogeneous size of coal that is shipped. This screening not only prevents non-metal contamination but also metal contamination.

5. Auto-Sampler Sampling & Dedicated Laboratorium Analysis

To monitor the homogeneous coal quality, sampling is done using Auto-Sampler.

With a dedicated laboratory, the sample analysis is obtained quickly and precisely during the loading process to the ship.